Master Planning

This is a Result if a

Production (BOM) and a Batch production order

(Formula), it can also be dome for default item set for Purchase and Sales.

How to Do it. Go to

Make sure item default is set as Production (Safety stock is need for BOM/Formula)

For item type default set as Purchase or

Sales – just run the Master planning and based on coverage setting you will get

the planned purchase order or planned production Order.

Master Planning - Basic Setup

1.

Item Coverage

2.

Forecast Plan

3.

Master Plan

4.

Coverage Group

5.

Master Planning Parameters

Item Coverage Note if you have Min/Max coverage on Master

planning parameter the only you can set Max Qty on Hand on Maximum key

(Highlighted in yellow on 1st screenshot)

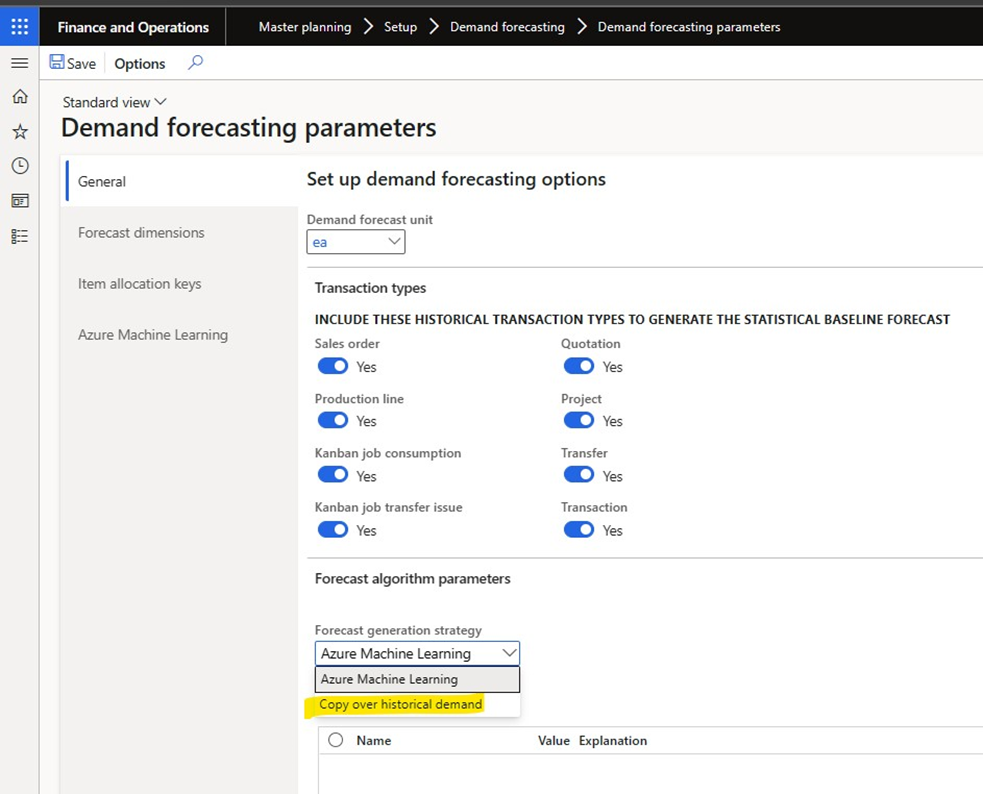

Master planning with demand forecasts - Supply Chain Management | Dynamics 365 | Microsoft Learn

Demand forecasting is used to predict independent demand from

sales orders and dependent demand at any decoupling point for customer orders.

The enhanced demand forecast reduction rules provide an ideal solution for mass

customization.

Coverage

1.

Minimum/Maximum Key

2.

Safety Stock

3.

Safety stock line

Forecast

1.

Item Allocation Key

2.

Period allocation Key

3.

Reduction Key

Note : If you select None, the forecast

requirements aren't reduced during master scheduling. In this case, master

planning creates planned orders to supply the forecasted demand (forecast

requirements). These planned orders maintain the suggested quantity, regardless

of other types of demand. For example, if sales orders are placed, master

planning creates additional planned orders to supply the sales orders. The

quantity of the forecast requirements isn't reduced.

Item allocation keys establish groups of items. A demand forecast is calculated for an item and its dimensions only if the item is part of an item allocation key. This rule is enforced to group large numbers of items so that demand

forecasts can be created more

quickly.

If you select Percent

- reduction key, the forecast requirements are reduced according to the

percentages and periods that are defined by the reduction key. In this case,

master planning creates planned orders where the quantity is calculated as forecasted

quantity × reduction key in each period. If there are other types of demand,

master planning also creates planned orders to supply that demand.

Using a Period Allocation Key- , allows you to build a profile of the period breakdown of your forecast. This profile is then used by Master Planning to generate planned production/purchase orders with the appropriate requirement dates assigned to them.

Comments